fatigue and creep testing|strain versus time creep curve : inc What is the difference between creep test and fatigue test? Creep testing measures how a material deforms under constant load over time, while fatigue testing examines how it responds to repeated cyclic loading. webThe easiest way to help the project is to sort channels by country. Specifically for this was created playlist channels/unsorted.m3u which contains channels that are not yet sorted by other playlists. If you recognize one of the channels in this playlist, just copy its title and link to the desired country playlist.

{plog:ftitle_list}

Resultado da 19 de out. de 2023 · The subscription price for Sophie Lawson’s OnlyFans is $4.95 for 31 days. It’s a good deal because she offers exclusive nude, solo, and explicit content that you won’t find elsewhere. Analyzing the Pros and Cons of Subscribing to @sophielawson_x on OnlyFans. In conclusion, I .

How to test for metal creep or fatigue in metals. The very earliest stages of creep failure happen on a molecular level and aren’t visible to the naked eye. Creep failure testing is the only way to be sure that products with metal components can withstand pressure long-term. The focus of the procedure is on tests in which creep and fatigue deformation and damage is generated simultaneously within a given cycle. It does not cover block cycle testing .

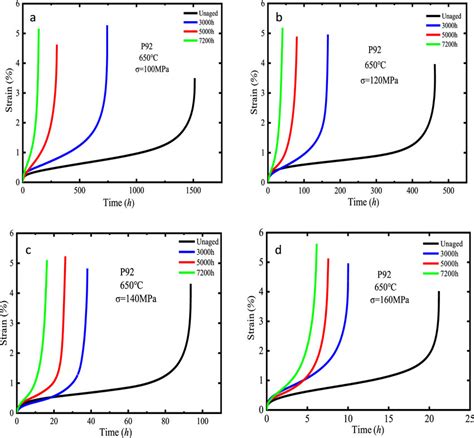

strain versus time creep curve

The creep–fatigue interaction behavior of materials is frequently simulated in the laboratory by high-temperature low-cycle fatigue (HTLCF) or creep-fatigue crack growth (CFCG) tests with .

The subsequent sections of this report examine, in detail, current design practice for basic creep- fatigue damage evaluation, creep-fatigue damage evaluation in the presence of detrimental .What is the difference between creep test and fatigue test? Creep testing measures how a material deforms under constant load over time, while fatigue testing examines how it responds to repeated cyclic loading. Creep testing involves the application of a prolonged constant tensile or compressive stress to a material specimen at constant temperature. The force may be applied .

Accelerated testing is a technique that reduces the time and cost of fatigue and creep testing by applying higher loads or temperatures than the service conditions, and extrapolating the results .The development of creep testing methods and the formulation of creep laws, such as the Norton-Bailey law, have been instrumental in predicting creep behavior in materials. . on fatigue analysis to ensure the durability of components such as engine parts, suspension systems, and chassis. Fatigue testing and analysis help in predicting the .Electric Power Research Institute 3420 Hillview Avenue, Palo Alto, California 94304-1338 • PO Box 10412, Palo Alto, California 94303-0813 USA 800.313.3774 • 650.855.2121 • [email protected] • www.epri.com 2010 TECHNICAL REPORT Creep-Fatigue Testing and Assessment Guideline The END • No Lab for Fatigue and Creep! • Hardness testing this week! • Have fun!! Fatigure and Creep. Related; More by User; Creep and Superplasticity. Creep Strain vs.Time: Constant Temperature. Creep Strain vs. Time at Constant Engineering Stress. Creep machine with variable lever arms to ensure constant stress on specimen; note that .

This STP contains 16 peer-reviewed papers that promote innovative accelerated testing and predictive tools to characterize creep, fatigue, and environmental cracking behaviors of engineering materials, and collect information, knowledge, and supporting documents for updating existing ASTM International standards in the areas of fatigue, creep, and environmental . Creep tests were carried out under the guidelines provided in . Tests (constant or variable loads) were always started at about 10 min after stabilizing the sample temperature to 600 °C. The temperature of a sample during the fatigue tests (program f) and creep tests (program c) was maintained automatically by the heating chamber control system.

Preliminary creep-fatigue test matrix for Alloy 709. ... 18. iv ABBREVIATIONS, ACRONYMS, AND INITIALISMS ANL Argonne National Laboratory AOD argon-oxygen-decarburization ART Advanced Reactor Technologies ASME American Society of Mechanical Engineers ASTM American Society for Testing and Materials . In addition, several creep tests were conducted. The high-temperature mechanical properties of the IFW joints were systematically analyzed. Under the creep testing condition of 680°C, the specimens exhibited creep fracture at the thermomechanically affected zone (TMAZ) of the PM superalloys. The creep-fatigue load spectrum is shown in Fig. 1 (b), where t h is the dwell time with hold stress and t p represents the time spends per cycle. All stress-controlled experiments share a same stress ratio R of 0.1 and the load/unload rates were fixed at 14.645 MPa/s. Creep-fatigue loads were repeated until the failure of specimen.Creep-fatigue is the initiation and subsequent growth of flaws under cyclic load interspersed with hold periods at constant, or slowly varying, load. . controlled fatigue test with holds will fail in fewer cycles than an equivalent pure fatigue test with the same strain range and at the same temperature but without any hold periods. Similarly .

creep rate as a function of temperature and applied stress. The constant A, the exponent n, and the activation energy for creep Qc are material characteristics and can be determined from a series of creep tests. Several tests have to be carried out .An experimental technique for the elevated temperature tensile fatigue and creep testing of fiber-reinforced ceramics is discussed. The experimental approach utilizes edge-loaded specimens with rectangular gage-sections. Novel furnace and grip designs which allow testing in air to 1500°C are provided.

It explores the advanced software tools for materials testing. The article includes a description of baseline isothermal fatigue testing, creep-fatigue interaction, and thermomechanical fatigue. The effects of various variables on fatigue resistance and guidelines for .

Fatigue and creep are fundamental mechanical properties of materials. Fatigue is the failure of a material caused by repeated application of cyclic stresses, even if the stresses are below the yield strength of the material. . The extent of the crack propagation process depends upon the brittleness of the material under test. In brittle . In addition, several LCF tests were performed for a low strain rate of 1 × 1 0 − 4 /s and as fatigue–creep tests with a tensile strain dwell. TMF tests were performed as out-of-phase and fully constrained between 100 °C and 650 °C. The investigation of the damage mechanisms revealed that the predominant failure mode is a combination of .fatigue tests, creep rupture tests, and static tensile tests are used as the reference for Lcreep Dcreep 1 = LLCF DLCF 1 = D = DLCF + Dcreep D = DLCF +Dbcreep. 5 predicting the number missions a component can survive under a given thermo-mechanical loading condition. Several analyses consisting of a number of mission

The term creep-fatigue testing shall incorporate continuous cycle fatigue testing for the remainder of this document. 2. PRECAUTIONS AND LIMITATIONS 2.1 Idaho National Laboratory (INL) Performer-Controlled Activities (PCA) LST-551, LST-552, or LST-553 are applicable while operating the mechanical testing systems.Metallic Materials - Uniaxial Creep Testing in Tension. BS 3500: Methods for Creep and Rupture testing of Metals. ASTM E139: Conducting Creep, Creep Rupture and Stress Rupture Tests of Metallic Materials. BS EN ISO 899: Plastics - Determination of Creep Behaviour. BS EN 761: Creep Factor Determination of Glass - Reinforced Thermosetting Plastics

difference between fatigue and creep

Fractue fatigue and creep - Download as a PDF or view online for free . the continuing change in the deformation of materials at elevated temperatures • Four variables measured during a creep test are stress, strain, temperature and time. 35 36. Creep curves • Shows the relationship between creep strain vs time at a particular . Typically such diagrams are constructed from the results of cyclic/hold (LCF with hold time) creep-fatigue tests or thermo-mechanical fatigue (TMF) tests, which indicate the extent of any creep-fatigue interaction of the material of interest under precisely known thermo-mechanical boundary conditions (e.g., insets in Figure 4 and Figure 5).

Creep-fatigue interaction behavior of ferritic steels and austenitic stainless-steels — covers properties, test methods and the latest models for applying the test data to components. Creep-fatigue interactions in nickel-base superalloys being considered for use or already in use in advanced nuclear plants and in gas turbines — discusses . A creep testing machine with a constant temperature chamber was used to perform the creep tests at three uniform temperatures. The fatigue tests were performed by using an electroservo-controlled hydrotesting machine with a constant temperature chamber at various frequencies, temperatures, and stress ratios. 11.3.2. Flexural CSR strength

Creep, Fatigue and Creep–Fatigue Interaction are among the major life limiting factors affecting the deformation and damage behaviour of components used in several high temperature applications including nuclear, aerospace, petrochemical and offshore industries.A thorough understanding of the material behaviour under the above loading conditions is . 1.3 Two types of creep behavior are generally observed in materials during creep-fatigue crack growth tests: creep-ductile and creep-brittle (1) 2.For highly creep-ductile materials that have rupture ductility of 10 % or higher, creep strains dominate and creep-fatigue crack growth is accompanied by substantial time-dependent creep strains near the crack tip.

Creep-fatigue testing combines cyclic mechanical loading with constant or variable temperature to evaluate the effects of both fatigue and creep on a material or product. These tests are used to .be good measures for the predictability of creep-fatigue models when creep dominates. The creep fatigue tests with the relatively short hold times in stress control do produce extensively larger creep strains than corresponding relaxation tests but . The fatigue crack initiation resistance of an alloy is determined by conducting a series of tests over a range of values of stress amplitude or strain range. The observed number of cycles to failure is plotted against the stress amplitude or strain range to obtain a fatigue curve. The fatigue properties quoted for an alloy are typically the constants used in the equation(s) .

creep testing machine diagram

12mm compression test hose adapter bmw

12mm compression tester extension

12mm compression tester hose

30 de out. de 2023 · Brasil – O streamer Mucalol foi surpreendido durante uma live após casal aparecer em um momento íntimo durante a transmissão ao vivo.Mucalol se mostrou perplexo e sem ração com a cena. Durante uma live, enquanto conversava com uma mulher, um homem aparece de forma inesperada e logo em seguida o casal é flagrado .

fatigue and creep testing|strain versus time creep curve